Welcome, fellow process manufacturing enthusiast! If you’re in the market for ERP software to streamline your operations, you’ve come to the right place. Choosing the best ERP software for process manufacturing can be a daunting task, but fear not – we’re here to guide you through the process. From inventory management to production scheduling, we’ll help you identify the key features to look for in an ERP system that will meet your specific needs. Let’s dive in and find the perfect solution for your manufacturing business!

Understanding Process Manufacturing

Process manufacturing is a method of production that involves using formulas or recipes to create products. This type of manufacturing is commonly used in industries such as pharmaceuticals, food and beverage, chemicals, and more. Unlike discrete manufacturing, which involves the production of distinct items like cars or appliances, process manufacturing focuses on creating products that are produced in bulk quantities through a series of interrelated processes.

In process manufacturing, raw materials are combined and transformed through a series of chemical or mechanical processes to create the final product. These processes often require precise measurements and strict adherence to formulations in order to ensure the quality and consistency of the end product. For example, in the production of pharmaceuticals, the exact combination of ingredients and the order in which they are added can have a significant impact on the effectiveness and safety of the final medication.

Process manufacturing also typically involves the use of specialized equipment and machinery to carry out the various stages of production. This can include reactors, mixers, distillation columns, and other devices that are specifically designed to handle the unique requirements of the manufacturing process. In addition, process manufacturing often involves the use of automated systems and control software to monitor and regulate the production process, ensuring that everything runs smoothly and efficiently.

One of the key challenges of process manufacturing is managing the complexity and variability of the production process. Since many factors can impact the quality of the final product, such as variations in raw materials, changes in environmental conditions, or fluctuations in demand, manufacturers must be able to adapt quickly and effectively to ensure that their products meet the required standards. This can require sophisticated planning and scheduling systems, as well as robust quality control measures to minimize the risk of defects or inconsistencies in the final product.

Overall, process manufacturing plays a crucial role in many industries by providing the foundation for the production of a wide range of essential goods. By understanding the unique characteristics and challenges of process manufacturing, businesses can optimize their production processes, improve product quality, and remain competitive in the marketplace.

Key Features of ERP Software for Process Manufacturing

When it comes to ERP software for process manufacturing, there are several key features that are essential for streamlining operations and increasing efficiency. These features are designed to meet the specific needs of process manufacturers, who rely on precise and consistent production methods to create their products. Below are some of the key features that are crucial for ERP software for process manufacturing:

1. Batch Process Management: One of the most important features of ERP software for process manufacturing is batch process management. This feature allows manufacturers to track and manage the production of goods in batches, ensuring consistency and quality control throughout the manufacturing process. With batch process management, manufacturers can easily monitor the progress of each batch, track raw materials and ingredients, and identify any issues or deviations in the production process.

2. Recipe Management: Recipe management is another essential feature of ERP software for process manufacturing. This feature allows manufacturers to create and store recipes for their products, detailing the exact quantities of each ingredient and the specific production instructions. With recipe management, manufacturers can easily replicate successful production runs, ensure consistency in their products, and quickly make adjustments to recipes as needed. Additionally, recipe management can help manufacturers track and trace ingredients throughout the production process, ensuring compliance with regulatory requirements and quality standards.

3. Quality Control: Quality control is a crucial aspect of process manufacturing, and ERP software plays a key role in ensuring that products meet the high standards set by manufacturers. ERP systems for process manufacturing often include robust quality control features that allow manufacturers to set and monitor quality benchmarks, conduct inspections and tests, and track any issues or defects in the production process. With quality control features, manufacturers can quickly identify and resolve quality issues, reduce waste and rework, and ensure that only high-quality products are shipped to customers.

4. Inventory Management: Effective inventory management is essential for process manufacturers, who must keep track of raw materials, work-in-progress inventory, and finished goods. ERP software for process manufacturing often includes advanced inventory management features that enable manufacturers to track the movement of materials and products throughout the production process, optimize inventory levels, and minimize stockouts and overstock situations. By effectively managing inventory, manufacturers can reduce costs, improve production efficiency, and enhance customer satisfaction.

5. Regulatory Compliance: Process manufacturers are subject to a variety of regulatory requirements, including food safety regulations, environmental regulations, and industry standards. ERP software for process manufacturing often includes features that help manufacturers ensure compliance with these regulations, such as tracking the use of controlled substances, maintaining accurate documentation, and providing audit trails for regulatory agencies. By using ERP software to manage regulatory compliance, manufacturers can avoid costly fines and penalties, protect their reputation, and demonstrate their commitment to producing safe and sustainable products.

Benefits of Implementing ERP Software in Process Manufacturing

Implementing ERP software in process manufacturing can bring numerous benefits to the business. Here are some key advantages:

1. Streamlined Operations: ERP software integrates all aspects of the manufacturing process into a single system, allowing for better coordination and communication between departments. This streamlines operations by eliminating the need for separate software for different functions, reducing manual data entry and the risk of errors.

2. Real-time Data Access: With ERP software, manufacturers can access real-time data on inventory levels, production schedules, and sales trends. This allows for better decision-making and helps in managing resources more efficiently. Managers can track the progress of orders, monitor employee performance, and quickly respond to changing market demands.

3. Cost Savings: Implementing ERP software can result in significant cost savings for process manufacturers. By automating processes and reducing manual tasks, companies can save on labor costs. Additionally, with better visibility into inventory levels, businesses can minimize the risk of stockouts and overstocking, leading to reduced carrying costs and improved cash flow.

Moreover, ERP software can help in optimizing production processes, reducing waste, and improving overall efficiency. By identifying bottlenecks in the manufacturing process, businesses can make informed decisions to increase productivity and meet customer demands more effectively.

In conclusion, implementing ERP software in process manufacturing can lead to increased efficiency, improved decision-making, and cost savings. With streamlined operations, real-time data access, and optimized processes, businesses can stay competitive in the fast-paced manufacturing industry.

Choosing the Right ERP Software for Your Process Manufacturing Business

Choosing the right ERP software for your process manufacturing business is a crucial decision that can impact the efficiency, productivity, and profitability of your operations. With so many options available in the market, it can be overwhelming to select the best fit for your unique business needs.

First and foremost, it is important to assess the specific requirements of your process manufacturing business. Consider factors such as the size of your operations, the complexity of your production processes, the number of users who will be using the software, and any specific industry regulations that you need to comply with. This will help you narrow down your options and focus on solutions that are tailored to your business needs.

Next, consider the scalability and flexibility of the ERP software. As your business grows and evolves, you need a software solution that can grow with you and adapt to changes in your operations. Look for ERP software that offers modules and functionalities that can be easily customized and expanded to meet your changing business requirements.

Another important factor to consider is the integration capabilities of the ERP software. Process manufacturing businesses often rely on a variety of systems and tools to manage different aspects of their operations, such as inventory management, production scheduling, and quality control. A good ERP solution should be able to seamlessly integrate with these systems and provide a unified platform for managing all aspects of your business.

Furthermore, consider the user-friendliness of the ERP software. Your employees will be using the software on a daily basis, so it is important that it is intuitive and easy to use. Look for ERP solutions that offer a modern and user-friendly interface, as well as comprehensive training and support resources to help your team get up to speed quickly.

Lastly, consider the cost and return on investment of the ERP software. While cost is an important factor to consider, it is also important to evaluate the long-term benefits and ROI that the software can provide to your business. Look for ERP solutions that offer a good balance between cost and value, and consider factors such as the potential for increased efficiency, productivity, and profitability that the software can bring to your business.

By taking these factors into consideration and carefully evaluating your options, you can choose the right ERP software for your process manufacturing business that will help streamline your operations, improve decision-making, and drive growth and success in the long run.

Best Practices for Successful Implementation of ERP Software in Process Manufacturing

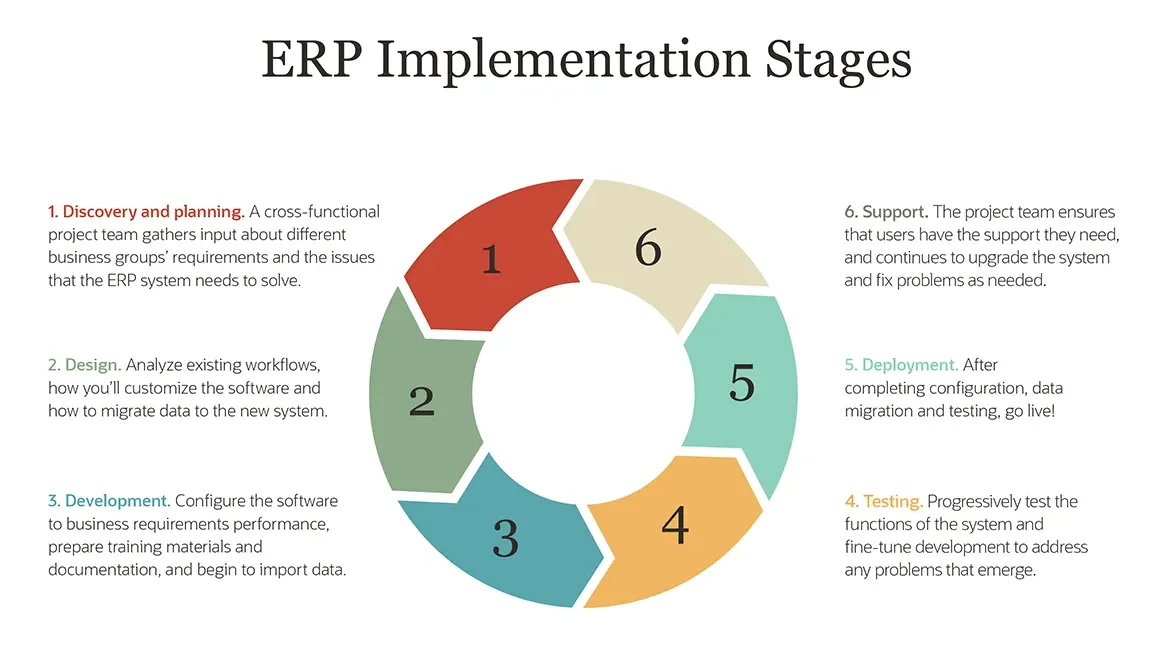

Implementing ERP software in process manufacturing can be a daunting task. However, with proper planning and execution, it can lead to significant improvements in efficiency, productivity, and profitability. Here are some best practices to ensure successful implementation:

1. Understanding the Needs of the Business: Before even considering implementing ERP software, it is crucial to fully understand the needs and requirements of your process manufacturing business. This includes identifying pain points, inefficiencies, and areas where improvement is needed.

2. Selecting the Right ERP Solution: Choosing the right ERP software for your process manufacturing business is essential. Look for a solution that is specifically designed for process manufacturing and has the features and functionalities that align with your business needs. It is also important to consider scalability and flexibility for future growth.

3. Engaging Stakeholders: It is important to involve key stakeholders from various departments in the implementation process. This includes employees from production, operations, finance, IT, and senior management. Their input and buy-in are crucial for successful implementation.

4. Providing Adequate Training: Training is essential for ensuring that employees can effectively use the new ERP software. Provide comprehensive training sessions for all employees who will be using the system, and offer ongoing support and resources for continuous learning.

5. Testing and Quality Assurance: Before fully implementing ERP software in process manufacturing, it is critical to thoroughly test the system to ensure that it meets the business requirements and functions properly. This includes testing various scenarios, data migration, integration with existing systems, and performance testing. Quality assurance measures should be put in place to identify and address any issues before the software goes live.

Originally posted 2024-01-06 09:33:34.